Your Cart is Empty

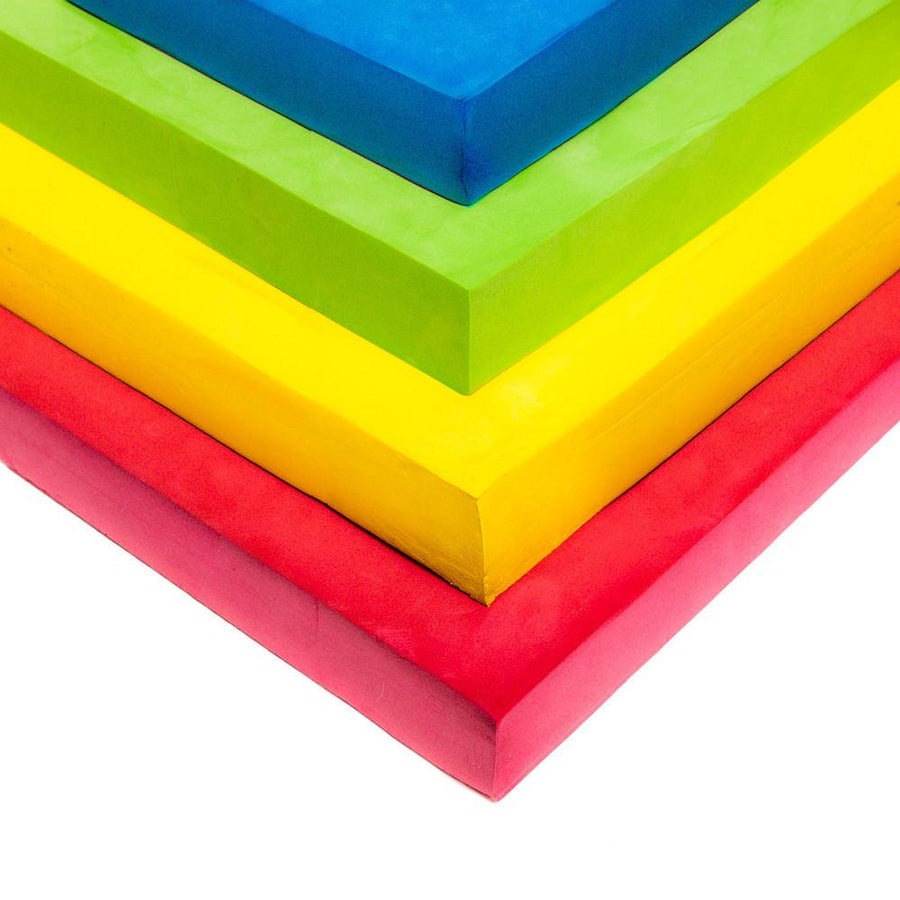

Polyethylene and EVA Foams are flexible or semi-rigid, closed cell foams made from low density polyethylene (LDPE) bead material.

Most industrial polyethylene foams are manufactured by LDPE bead expansion, followed by block moulding, or by extrusion of the liquid formulation through an oven where further expansion takes place to achieve the required sheet density. The expanded product is then cut to sheet length or rolled, as required.

Polyethylene foam is renowned for its ability to bear up under pressure without losing its original form and cushioning properties, and to withstand elongation before breaking. These characteristics make it the ideal foam for applications where both support and durability are important. This elastic property of polyethylene, (which is even greater for EVA), combined with its non-abrasive, light weight, buoyancy, resistance to oils, solvents and chemical attack, odourless and affordability qualities, contribute to making polyethylene the world’s most popular and versatile thermoplastic polymer. Polyethylene foam products are durable, reusable and 100% recyclable where plastic recycling is available.

A summary of the characteristics of Polyethylene-Based (PE & EVA) foams includes:

- Non-abrasive, providing good surface protection without scratching

- Clean and non dusting

- Flexible, compressible, shock absorbing, vibration dampening and cushioning

- Resilient, long term rebound, and compressive recovery

- Consistency, dimensional stability, and good compressive creep properties

- High load bearing capacity

- Lightweight with low embedded energy

- High thermal resistance / low thermal conductivity

- Moisture, water and air impermeability

- Odourless and inert

- Bacteria, fungi and chemical resistant

- Cost and labor efficient

- Non-corrosive

- Excellent dielectric properties

- Buoyant

- CFC free, ozone friendly, and recyclable

So there are plenty of reasons why Polyethylene EPE, PE and EVA foams are so popular!

For Product Data and Technical Information on all Foam Sales' Polyethylene and EVA Foam ranges see our Data Sheets.